Industrial roofing solutions have a significant place in the construction sector, which is booming today. Durable, efficient, and long-lasting performance are the main features of industrial roofing. Every project, whether it is a warehouse or a pre-engineered building, needs roofing that is made both technically and quickly. Thus, the roof sheet making machines go on – the most advanced systems that are designed to meet every industry’s demand for such roofing sheets of high quality.

At Sri Gajanana Cranes and Hoists, we are proud to offer our customers the most innovative, durable, and high-performing roof sheet roll forming machines that integrate the latest technology. Simplified production, increased efficiency, smooth compatibility with EOT cranes and industrial sheds, are the benefits these machines provide to the users, who now get a complete roofing sheet solution under one roof.

Why Choose Our Roof Sheet Making Machines?

The production of roof sheets is not just about cutting and shaping. The process requires accuracy, consistency, and dependability to satisfy the demands of modern infrastructure projects. The roof sheet making machines that we provide are constructed with these goals at the forefront.

Our roll forming systems are designed for the manufacturers of roofing sheets, fabricators of steel, and construction companies, enabling them to produce various kinds of sheets such as:

- Galvanized roofing sheets

- Color-coated metal roofing sheets

- PPGI (Pre-painted Galvanized Iron) roof panels

Our machines with advanced PLC-controlled automation minimize human error, lessen dependency on labor, and maximize output. The end-product will be roofing sheets that ensure the accuracy of the shape, have smooth finishing, and consistent quality from large-scale production.

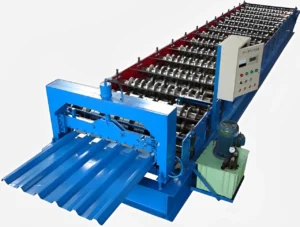

Roof sheet making machine roll forming system

Key Features & Benefits

Every roofing sheet roll forming machine from Sri Gajanana Cranes and Hoists is tailored to provide excellent performance, long service life, and user convenience. Some of the highlights of the product are:

- Customizable Roofing Profiles – Corrugated, trapezoidal, and step-tile sheet are some of the options that the users can select to fit the project requirements.

- PLC-Controlled Roll Forming – Facilitates higher production speed while ensuring precision forming and cutting.

- Hydraulic Cutting & Stacking Unit – Makes sure that sheet cutting is clean, accurate, and consistent.

- High-Grade Chromium Steel Rollers – These are tough and long-lasting rollers that also feature smooth edges and low wear.

- Multi-Coil Support – It can be used with galvanized coils, color-coated coils, and PPGI coils.

- High-Speed Output – The production speed is between 20 and 30 meters per minute which allows for delivery of the project on time.

- Low Maintenance – The design is for continuous operations with a high number of operating hours and low downtime.

- Complete Plant Integration – The product is compatible with crane systems and shed structures which makes it easy to handle and store.

These advantages are some of the reasons why our machines are the preferred ones for businesses that value reliability, efficiency, and long-term savings.